drive into the future with the 2025 subaru forester...

November 27, 2025

7:49 am

want an suv with easy access and comfort for seniors? here’s how to get it!...

November 27, 2025

7:44 am

Enhance Performance and Longevity: Upgrade Your Drive with a Lubrication-Free Coupling

November 27, 2025

07:50

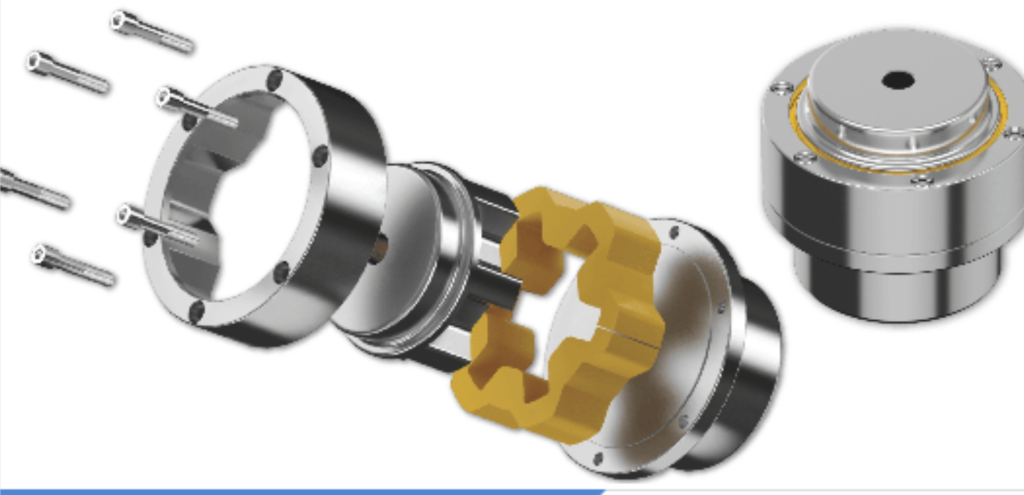

If you are looking for a smarter way to boost uptime, trim maintenance costs, and clean up your operation, it may be time to upgrade your drive with a lubrication-free coupling. These next-generation components replace messy, failure-prone grease points with engineered materials that run clean and last longer. The result is a quieter, more efficient drive that is easier to own and operate. This guide breaks down how lubrication-free couplings work, where they shine, how to pick the right one, and the best practices that keep them delivering for years.

Traditional couplings rely on a film of oil or grease to prevent metal-to-metal contact. Lubrication-free designs take a different route. They use self-lubricating polymers, engineered composites, or advanced metallic interfaces with embedded solid lubricants to keep friction low without added oil. These materials present a low coefficient of friction at the sliding or flexing interface, which sharply reduces wear while enabling smooth torque transfer.

Geometry matters just as much as materials. The flexible elements, teeth, or bushings are shaped to distribute load evenly, limit stress concentrations, and accommodate misalignment. This combination of smart geometry and self-lubricating surfaces allows the coupling to run cooler, resist fretting, and maintain alignment accuracy over long service intervals.

Recent Posts

celebrate the holidays in a new hyundai palisade...

November 27, 2025

7:39 am

explore surprisingly affordable luxury ram 1500...

November 27, 2025

7:48 am

need a new car? rent to own cars no credit check ...

November 27, 2025

7:36 am

explore the 2025 jeep compas: adventure awaits!...

November 27, 2025

7:31 am

Self-lubricating elements rely on microscopic transfer films that renew during motion. As the coupling flexes under torque and misalignment, a thin, uniform layer forms at the interface and continuously refreshes. With no liquid lube to migrate or dry out, there is nothing to drip, attract dust, or oxidize. That means no relubrication schedules, no purge cycles, and no contamination risk from oil escaping into surrounding processes.

Eliminating periodic relubrication tasks removes a recurring line item from your maintenance plan. There are no grease points to reach, no cartridges to replace, and no seals to fail due to lubricant breakdown. That lowers labor hours and reduces the chance of errors that lead to premature wear. In many plants, a single avoided unplanned stop can pay for the coupling upgrade several times over.

No oil means no leaks, stains, or absorbent pads. Housekeeping improves, slip hazards are reduced, and sensitive processes benefit from a lower risk of contamination. Many facilities now measure environmental performance and waste streams. Lubrication-free couplings help you hit those goals by removing a persistent source of oily waste and plastic grease cartridges.

Recent Posts

2025 jeep wrangler price one might not want to miss!...

November 27, 2025

7:22 am

drive into the future with the 2025 subaru forester...

November 27, 2025

7:23 am

want an suv with easy access and comfort for seniors? here’s how to get it!...

November 27, 2025

7:45 am

celebrate the holidays in a new hyundai palisade...

November 27, 2025

7:29 am

Greases thicken in cold environments and thin in extreme heat. Dust and chemicals can also degrade lubricants or clog seals. Self-lubricating materials are formulated to hold their properties across wide temperature ranges and dirty conditions. That makes these couplings strong candidates for outdoor conveyors, food and pharma equipment that must stay clean, and applications with chemical exposure.

A coupling that holds its internal friction low without maintenance runs more consistently. With less internal loss and less heat generation, more of the motor’s work reaches the load. That consistency also improves control performance for systems that depend on accurate speed, position, or tension.

High-performance polymers such as polyamides and PEEK-based compounds, often filled with PTFE, graphite, carbon fiber, or glass, deliver low friction with excellent fatigue resistance. These materials are molded or machined into flexible elements, bearing sleeves, or tooth liners that absorb shock and accommodate misalignment.

Recent Posts

explore surprisingly affordable luxury ram 1500...

November 27, 2025

7:32 am

need a new car? rent to own cars no credit check ...

November 27, 2025

7:24 am

explore the 2025 jeep compas: adventure awaits!...

November 27, 2025

7:39 am

2025 jeep wrangler price one might not want to miss!...

November 27, 2025

7:42 am

Some designs use precision metal parts combined with solid lubricants or surface treatments that embed lubricious phases into the wear layer. These finishes provide the hardness and thermal stability of metal while reducing friction at the contact surface.

High torque and high speed place different demands on a coupling. A high-speed spindle may need a lightweight polymer element with excellent dynamic balance and low hysteresis heating. A heavy-duty mixer may favor a composite with high compressive strength and shock resistance. The right pairing of base resin, fillers, and geometry is what unlocks long life without grease.

When crews are not pausing equipment to relube couplings or clean leaked oil, production keeps moving. Fewer stoppages translate into more finished product, better schedule adherence, and lower overtime.

Recent Posts

drive into the future with the 2025 subaru forester...

November 27, 2025

7:43 am

want an suv with easy access and comfort for seniors? here’s how to get it!...

November 27, 2025

7:46 am

celebrate the holidays in a new hyundai palisade...

November 27, 2025

7:23 am

explore surprisingly affordable luxury ram 1500...

November 27, 2025

7:49 am

Lubrication events introduce variability. Skip one, and wear spikes. Overdo it, and seals can fail. With lubrication-free designs, degradation is gradual and tied to known load, speed, and misalignment profiles. That makes life modeling easier and replacement planning more precise.

Less internal rubbing means lower temperature rise around the coupling. Cooler operation protects nearby bearings and seals and can support longer lubricant life in adjacent components that still require oil, such as gearboxes. Any reduction in internal loss also nudges energy consumption in the right direction.

Switching away from oil or grease in even a handful of couplings removes a surprising amount of waste over a year. Many organizations highlight those savings in sustainability reports. If your customers audit environmental practices, a move to lubrication-free elements sends a positive signal.

Recent Posts

need a new car? rent to own cars no credit check ...

November 27, 2025

7:26 am

explore the 2025 jeep compas: adventure awaits!...

November 27, 2025

7:31 am

2025 jeep wrangler price one might not want to miss!...

November 27, 2025

7:30 am

drive into the future with the 2025 subaru forester...

November 27, 2025

7:33 am

Torque and service factor: Determine continuous and peak torque, then apply a service factor that reflects starts, stops, and shocks.

Space and connection: Check hub lengths, OD limits, and your shaft interfaces, including keyways, clamping hubs, or splines.

Look for suppliers that publish clear ratings, test to recognized standards, and can provide application engineering. Ask about material traceability, fatigue testing, chemical compatibility data, and temperature performance. Strong support during selection and installation avoids costly misapplications later.

Recent Posts

want an suv with easy access and comfort for seniors? here’s how to get it!...

November 27, 2025

7:45 am

celebrate the holidays in a new hyundai palisade...

November 27, 2025

7:46 am

explore surprisingly affordable luxury ram 1500...

November 27, 2025

7:43 am

need a new car? rent to own cars no credit check ...

November 27, 2025

7:32 am

Lubrication-free does not mean alignment-free. Clean mating surfaces, check runout, and use feeler gauges, dial indicators, or laser tools to set angular and parallel alignment within the coupling’s recommended limits. Proper alignment reduces internal deflection, heat, and wear and maximizes element life.

Use the manufacturer’s specified tightening sequence and torque for clamping hubs or setscrews. Verify key fit if keys are used. Recheck fasteners after initial run-in to account for any seating.

Record alignment measurements, fastener torques, shaft sizes, and installation dates. A simple log makes it easy to spot trends and plan replacements before performance suffers.

Recent Posts

explore the 2025 jeep compas: adventure awaits!...

November 27, 2025

7:36 am

2025 jeep wrangler price one might not want to miss!...

November 27, 2025

7:25 am

drive into the future with the 2025 subaru forester...

November 27, 2025

7:39 am

want an suv with easy access and comfort for seniors? here’s how to get it!...

November 27, 2025

7:26 am

Even without relube tasks, periodic checks are smart. Listen for new vibration or noise, feel for unusual heat, and look for dust build-up that might indicate misalignment or rubbing. If you trend motor current, torque ripple, or temperature near the coupling, a drift can be an early warning.

Increased backlash, cracked or permanently deformed elements, and rising temperature during steady operation point to replacement time. Because lubrication-free couplings tend to degrade predictably, you can set inspection intervals that line up with planned outages.

Sensors and compact transmitters are moving closer to the shaft. Expect more couplings with embedded health indicators that track temperature, vibration, and misalignment. That data feeds predictive maintenance systems and helps plants extend component life with confidence.

Recent Posts

celebrate the holidays in a new hyundai palisade...

November 27, 2025

7:23 am

explore surprisingly affordable luxury ram 1500...

November 27, 2025

7:41 am

need a new car? rent to own cars no credit check ...

November 27, 2025

7:24 am

explore the 2025 jeep compas: adventure awaits!...

November 27, 2025

7:39 am

Additive manufacturing and modular designs are shortening lead times for special geometries, unique bolt patterns, or tailored stiffness. Rapid prototypes can be tested in the field, then rolled into production with minimal delay.

Research into bio-based polymers and fully recyclable composites is accelerating. The goal is the same performance and life of current self-lubricating elements with a smaller environmental footprint from cradle to grave.

If your goals include higher uptime, cleaner operations, and lower total cost of ownership, the case to upgrade your drive with a lubrication-free coupling is compelling. Start by listing torque, speed, misalignment, and environment requirements. Engage an experienced supplier to match materials and geometry to your duty cycle. Install with care, align to spec, and track a few simple indicators over time.

The payoff is a drive train that runs cleaner, lasts longer, and asks less of your maintenance team. That means more production, more predictability, and a system that is better for your people and the planet.

Recent Posts

TL;DR In the new documentary The Age of Disclosure, U.S. Secretary of State Marco Rubio claims that unidentified objects have repeatedly entered restricted nuclear airspace—and that some governments may have kept the White House in...

December 11, 2025

11:45 am

2025 jeep wrangler price one might not want to miss!...

December 11, 2025

11:33 am

The Trump Gold Card visa is a fast-track residency option for wealthy foreign nationals who are willing to pay a $15,000 processing fee and contribute at least $1 million to the U.S. Treasury. It grants...

December 11, 2025

11:39 am

drive into the future with the 2025 subaru forester...

December 11, 2025

11:38 am

Akshaye Khanna’s performance in Dhurandhar has caught the internet off guard. His sharp-suited, cold-eyed gangster isn’t just a cinematic creation; it draws heavily from the real Rehman Dakait, one of Pakistan’s most feared crime divs....

December 11, 2025

11:17 am

want an suv with easy access and comfort for seniors? here’s how to get it!...

December 11, 2025

11:10 am

A startling cross-border investigation has revealed that an anonymous sperm donor carrying a dangerous cancer-causing gene variant fathered at least 197 children across Europe, exposing a critical gap in international donor screening and genetic regulation....

December 11, 2025

11:03 am

celebrate the holidays in a new hyundai palisade...

December 11, 2025

10:45 am

Every December, Spotify Wrapped takes over social media with colorful snapshots of listeners’ habits. Now, ChatGPT is joining the year-end trend with ChatGPT Wrapped, a personalized recap of how you’ve interacted with the AI throughout...

December 11, 2025

10:56 am

explore surprisingly affordable luxury ram 1500...

December 11, 2025

10:44 am

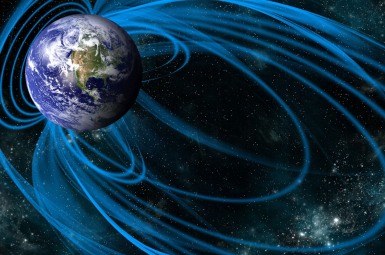

Most people associate cosmic tails with comets, those brilliant streams of gas and dust trailing behind icy bodies as they race around the Sun. But Earth, too, has a tail. And unlike a comet’s shimmering...

December 11, 2025

10:51 am

need a new car? rent to own cars no credit check ...

December 11, 2025

10:24 am